Occasionally in the course of Handyman Events there appears a curiosity wrapped in puzzlement within a wonderment. A “simple job” otherwise known technically as a “head scratcher”. A recent Bracket installation project was the very definition of just such a “simple job”.

I have ruminated about “simple jobs” in previous posts over the years. CLICK HERE or CLICK HERE or CLICK HERE

On the surface the assignment seemed straight forward enough: Drill 8 holes to attach 2 brackets with 4 lag bolts each. The brackets are to be used with suspension trainers, gym rings, yoga swings,hammocks, resistance or battle ropes.

But fun and hijinks began with the first instruction to wit: Drill a 1/2 inch hole. There is no place on these brackets where a 1/2 inch hole is desirable or necessary. To demonstrate this to the homeowner I drilled a 1/2 inch hole through a piece of scrap wood with a marked 1/2 inch spade bit. The supplied hex head lag bolts almost fell completely through the hole. Possibly the author confused the supplied plated 5/16 lag bolts with the fact that the bolt head itself requires a 1/2 inch socket to tighten or loosen. But that is the ONLY place the term 1/2 inch even enters the discussion.

So we settled on a twist drill diameter slightly smaller than the threaded shaft so the lag bolt would grab but tighten without excessive friction.

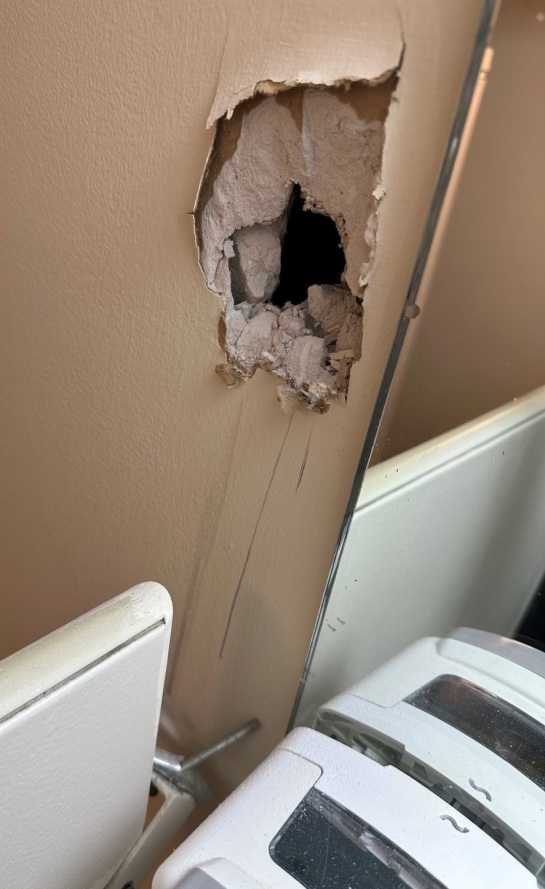

Without warning another speed bump immediately popped up. I cannot remember a rough lumber lag bolt EVER twisting apart while being tightened into an 8×8 post. If anything the socket on a 3/8 socket wrench is likely to crack before the bolt breaks! And that is only when used with extreme force to tighten a recalcitrant bolt. THIS bolt was easing into quietly into place when suddenly there were two pieces!

And THAT is when I noticed the supplied bolts came WITHOUT A HEADSTAMP.

For those who are unfamiliar headstamps are universally used to describe bolt characteristics, strength and manufacturer. Every hardware store sells only headstamped bolts in their inventory!

Headstamp identification PDF file CLICK HERE

Now I am looking at this deal with a magnifying glass, dare I say even a microscope if I had loaded one on the truck!

The instructions detail the number of bolts supplied as 2. However, there are 4 bolt holes in the bracket baseplate and 4 5/16 inch lag bolts supplied with each bracket. In a perfect world normal practice would dictate no two bracket holes be in line with each other along the lumber grain to prevent the possibility of splitting the wood. Generally this information would be communicated with a factory supplied template to indicate a suggested bolt layout. Every 10 dollar doorknob from China supplies a layout template for doorknob bore holes. Why this bracket would not have an equivalent template for bolt holes is a mystery.

Curiously the instructions DO have stern warnings about the load ratings required to use these brackets. 3750 lb shear load is alot to ask of most residential and commercial construction especially if the walls are metal stud construction.

Fascinating pretty relevant discussion about shear loads CLICK HERE

But the real question is WILL THE BRACKETS THEMSELVES STAND UP TO A 3750 lb load? For example some welds completely fill the surface gap and others not so much.

Sadly, I told the homeowner this whole setup is snakebit and these brackets might not do the job he wanted. Maybe some others might work better.

As Sgt. Esterhaus famously said “Let’s be careful out there”